LVT/LVP flooring is a kind of high quality decorative vinyl flooring, as high-tech research developed, new-type ground material, which is usually used in domestic and commercial areas. LVT/LVP flooring is mainly made of polyethylene and calcium carbonate with certain percentage. Polyethylene is environmentally non-toxic renewable resource. All the ingredients are non-toxic, non-radioactive and eco-friendly.

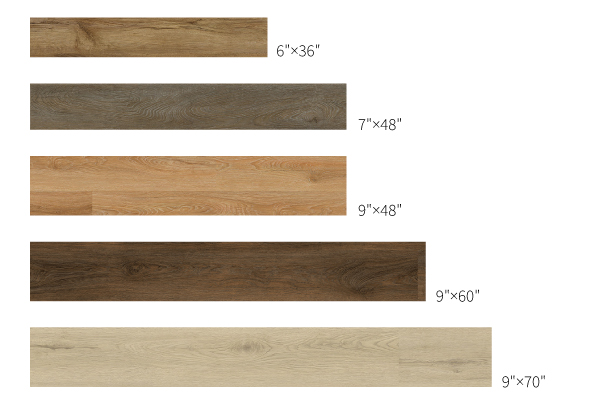

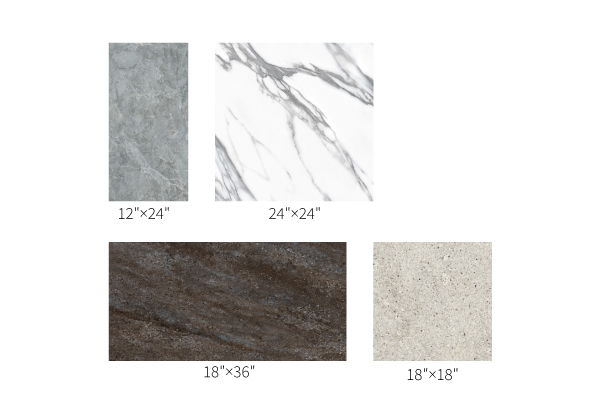

LVT/LVP floors have a realistic look and feel of solid wood or ceramic tile, they are extremely durable, easy to clean and maintain, and their versatile design makes them suitable for a wide range of decorating styles.

At present, it is a popular trend to use LVT flooring instead of solid wood flooring or ceramic flooring, because LVT flooring is safe, non-toxic, harmless, durable, comfortable to touch, and extremely cost-effective, making it an economical choice for home installation.

Trioflor is a LVT/LVP flooring manufacturer in China, with more than 25 years experience in vinyl flooring. We can produce LVT/LVP dry back, LVT/LVP glue down, LVT/LVP peel & stick, LVT/LVP self adhesive, Loose lay based on the different installation way. And we can provide 1.8 meter LVT/LVP flooring, herringbone flooring, random installation, based on the size. Besides, we also provide deep embossing/ BP texture, wood embossing/ wood texture, EIR, register embossing/ register texture. As a LVT/LVP flooring manufacturer and wholesaler, we are proud to offer a wide range of vinyl flooring, luxury vinyl tile flooring and luxury vinyl plank flooring for your business or client.

Trioflor is committed to providing high-quality, environmentally friendly, durable and beautifully designed flooring solutions to customers around the world. Our products carefully imitate the texture and color of natural wood and stone, and have excellent waterproof, scratch-resistant and wear-resistant properties, which can be perfectly adapted to both domestic spaces and commercial places.

We produce products for importers who have their own brands or are ready to establish their own brands, and provide OEM services.

Environmental

100% pure raw material with strict control, ensure the health of each user.

Safety

Fireproof, waterproof, moistureproof, mildewproof. Absolutely outstanding performance for any occasion.

PUR

The PU material coating enhance the flooring intensity and anti-scratch property, more service lifetime.

Quiet underfoot

Water resistant

Anti-bacterial

Easy to clean and maintain

Easy to install

Eco-friendly

Luxury Vinyl flooring is a waterproof hard surface floor that has the look and feel of hardwood. Also referred to as LVT/LVP, luxury vinyl is very affordable and extremely resistant to foot traffic, pets, and everyday household uses. LVT/LVP flooring is easy to maintain and has a wide variety of colors and styles.

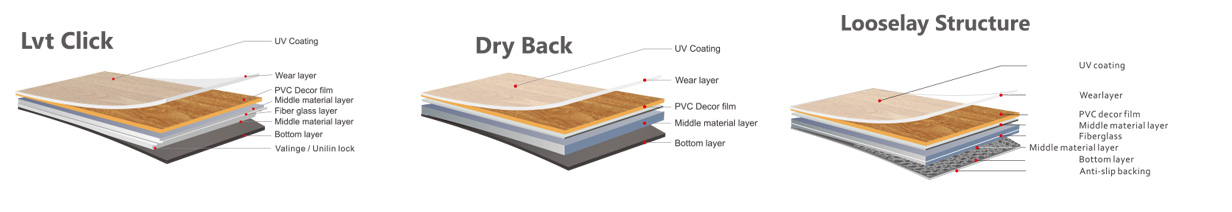

LVT flooring is made of multiple layers designed for durability and realistic appearance. Typically, it includes a protective wear layer that resists scratches and stains, a printed design layer that mimics wood, stone, or ceramic visuals, a flexible or rigid vinyl core for strength and stability, and a backing layer that adds support and moisture resistance. Some LVT products also include an attached underlayment for enhanced comfort and sound absorption. Together, these layers create a versatile, waterproof, and highly durable flooring solution for various residential and commercial applications.

Wear Layer

Transparent and durable.

Protects against scratches, stains, and daily wear.

Printed Design Layer

High-definition image mimicking wood, stone, or ceramic.

Gives LVT its realistic appearance.

Vinyl Core Layer

Provides strength, flexibility, and dimensional stability.

Can be flexible or rigid depending on product type.

Backing Layer

Supports the floor structure.

Adds moisture resistance and improves overall durability.

(Optional) Attached Underlayment

Adds sound absorption and cushioning.

Enhances walking comfort and reduces noise.

Trioflor is one of the first manufacturers to introduce the international advanced vinyl flooring production line in 2002, we specialise in the production and manufacture of LVT sheet flooring, supplying stable quality and cheap lvt flooring for private label owners.

| Unit | Result | |

| Total thickness | mm | 2.0/3.0 |

| Thickness of wear layer | mm | 0.1/0.2/0.3/0.5 |

| Surface treatment | - | PUR |

| ITEM | STANDARD | UNIT | RESULT |

| Length/Width | EN ISO 24342 | mm | ≤0.10% /≤0.50mm |

| Squareness/Straightness | EN ISO 24342 | mm | ≤0.25mm |

| Total thickness | EN ISO 24346 | mm | ±0.15mm |

| Wear layer | EN ISO 24340 | mm | ±0.05mm |

| Total mass per unit area | EN ISO 23997 | 一- | +13%/-10% |

| Peeling Strength of layer | EN 431 | — | >50N (50mm) |

| Residual indentation(average) | EN 433 | mm | <0.1 |

| Fire Resistance | EN 13501-1 | — | Bfl-S1 |

| Dimension stability after exposure to heat | EN 434 | % | <0.25 |

| Curling after exposure to heat | EN 434 | mm | <2.0mm |

| Color fastness to light | EN IS0105 B02 | — | grade>6 |

| Loss on heating | JIS A5705 | — | <0.5% |

| Change in length to water absorption | JIS A5705 | mm | <0.20mm |

Top vinyl flooring supplier is at your service

If you want to customize floorings for your own brands, or purchase for your projects.please leave a message here, we will send our quotation and arrange the delivery of freesamples as soon as possible.