Fire safety is not a nice-to-have; it’s a promise to your occupants. That’s why the SPC Wall Panel has become a go-to interior solution for hospitals, schools, hotels, and transit hubs. In this article, we explain how the SPC Wall Panel reaches reliable flame-spread control and lower smoke, and how a project team can keep that performance consistent from lab to jobsite.

If you’re shopping for an SPC Wall Panel today, use this as a plain-language guide rather than a technical lecture.

Modern codes and owners expect more than a pretty surface. A good SPC Wall Panel needs to slow flame travel, reduce smoke, avoid flaming drips, and stay stable under heat. Traditional finishes often struggle here, but an SPC Wall Panel combines a mineral-filled core with smart surface chemistry to raise the safety bar. Most importantly, that same SPC Wall Panel performance must survive real-world installation, not just test chambers and marketing claims.

1.What a realistic test report for an SPC Wall Panel should include.

2.How the material recipe inside an SPC Wall Panel works with its surface layers to resist ignition and curb smoke.

3.Which installation details make or break an SPC Wall Panel in an actual corridor, ward, or retail floor.

Before trusting any brochure, ask for third-party testing on the exact SPC Wall Panel you intend to buy: product name, thickness, layer stack, and the lab conditions.

Look for clear outcomes on flame spread, smoke density or smoke production, heat release, oxygen index, and whether there were flaming drips. The same SPC Wall Panel family can vary across batches, so a project should run a site mockup and, when anything changes—adhesive, sealant, or backing—recheck that the SPC Wall Panel still meets your project’s required classification and documentation.

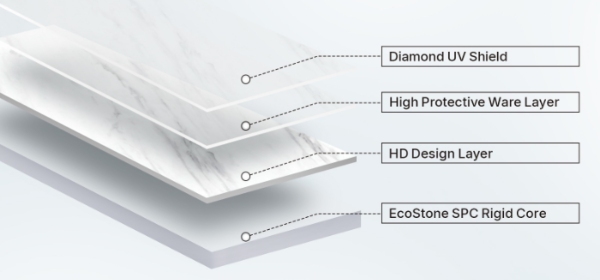

SPC wall panel internal material formula

A UV-cured topcoat and print layer sit above a functional wear layer, all protecting a mineral-rich composite core.

That core is where the SPC Wall Panel gets much of its fire behavior: minerals lower the amount of polymer fuel and soak up heat, while the base resin contributes self-extinguishing tendencies.

Add a modern smoke suppressant and a halogen-free flame-retardant package, and the SPC Wall Panel forms a tighter, more insulating char that slows flame spread, lowers smoke, and protects the layers underneath.

In practice, the SPC Wall Panel fights fire in three ways:

1.absorbing heat through mineral fillers,

2.creating a barrier layer (char) that blocks oxygen and volatile gases,

3.diluting fuel and stabilizing the surface so the SPC Wall Panel doesn’t drip or flash quickly.

SPC Wall Panel buys time for alarms, lighting, and people to do what they need to do. That extra time is often what separates a minor incident from a major loss.

Even the best SPC Wall Panel can underperform when details are overlooked.

Start with a compliant substrate or stud wall; for cavities, use metal studs and add cavity fire-stops so the SPC Wall Panel system doesn’t channel flames. Seal every perimeter and joint with a rated sealant that matches the SPC Wall Panel classification. Around penetrations—power points, data boxes, conduits—use proper fire collars or intumescent putty so the SPC Wall Panel face doesn’t hide a weak point. Avoid generic foams and unknown trims that can undermine the SPC Wall Panel system. Keep documentation of what went behind the surface so future maintenance can protect the SPC Wall Panel performance, not weaken it.

Lower smoke is more than a spec—visibility saves lives. Choosing a low-smoke recipe for the SPC Wall Panel supports safer egress and less damage to electronics. Pair the SPC Wall Panel with low-VOC adhesives and plan a short flush-out to keep air healthy after fit-out. Over the long run, the durable finish of the SPC Wall Panel reduces repair cycles and waste, and end-of-life recycling options for the SPC Wall Panel can further reduce the project’s footprint. Routine checks of edges and penetrations will keep the SPC Wall Panel system performing as specified.

Notes:

Flame-spread index: how fast flames move across a surface like an SPC Wall Panel.

Smoke density/production: how much visibility an SPC Wall Panel sacrifices when it burns.

Heat release rate: how fast energy is released; a disciplined SPC Wall Panel keeps this in check.

Flaming droplets: molten bits that can ignite other items—well-built SPC Wall Panel systems limit this risk.

· Always request third-party reports for the exact SPC Wall Panel and run a mockup before you commit.

· All Panel as a system: panel, substrate, studs, cavity fire-stops, sealants, and adhesives.

· Control the riskiest spots first: vertical cavities, perimeter joints, service penetrations, and door/window edges behind the SPC Wall Panel.

· Choose a low-smoke recipe for the SPC Wall Panel; it matters more for safe egress than raw flame ratings alone.

· Match every adhesive, sealant, and trim to the SPC Wall Panel fire classification—no unknown substitutes.

· Keep a photo log of hidden work so the SPC Wall Panel installation is auditable later.

· When operations change (new cable cutouts, bracket installs), bring the SPC Wall Panel back to its original fire-stopped condition.

· Publish plain-language data: list the SPC Wall Panel grade and key metrics, plus a way to verify reports.

· Remember: the best SPC Wall Panel is only as safe as the way it’s installed and maintained.

· Pick targets by building type: for hospitals, schools, and transit, specify more demanding smoke and flame goals for the SPC Wall Panel.